Packaging plays a crucial role in today’s fast-moving business environment. Whether a company deals with food, pharmaceuticals, or consumer goods, efficient packaging can save time, reduce costs, and improve overall productivity. One of the technologies that has revolutionized packaging is the vertical form fill seal (VFFS) machine. Working with vertical form fill seal machine manufacturers can significantly benefit businesses seeking to improve their packaging efficiency.

Understanding Vertical Form Fill Seal Machines

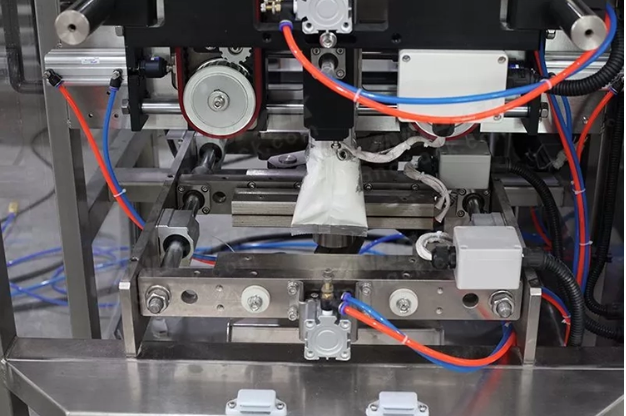

A vertical form fill seal machine is designed to automate the packaging process. It forms packages from a roll of film, fills them with the product, and seals them, all in one continuous process. This automation ensures speed, precision, and consistency, which are critical for businesses handling large volumes of products. By reducing manual labor, VFFS machines help companies focus on other aspects of their operations while maintaining high standards in packaging.

Benefits of Working with Vertical Form Fill Seal Machine Manufacturers

Collaborating with vertical form fill seal machine manufacturers provides businesses with access to expertise and technology tailored to their needs. These manufacturers not only supply the machines but also offer guidance on selecting the right equipment for specific products. For example, some machines are better suited for powders, while others handle liquids or granular items more efficiently. Manufacturers can advise on the best machine models to improve speed, minimize waste, and optimize the packaging workflow.

Enhancing Productivity and Speed

One of the main advantages of using a VFFS machine is the increase in productivity. Manual packaging can be slow and inconsistent, leading to delays and errors. Vertical form fill seal machines operate at high speeds, producing multiple packages per minute without compromising quality. By working closely with vertical form fill seal machine manufacturers, businesses can choose machines that match their production requirements, ensuring that the packaging process keeps pace with demand.

Ensuring Consistency and Quality

Consistency is essential in packaging, especially for consumer products. A well-packaged item attracts customers and builds brand trust. Vertical form fill seal machines are designed to provide uniform package sizes and seals, reducing the risk of leaks, spills, or damage. Vertical form fill seal machine manufacturers often include quality control features in their machines, such as automated check systems, which help businesses maintain a high standard of packaging without the need for constant manual inspection.

Reducing Waste and Operational Costs

Packaging waste can be costly, both in terms of material and labor. VFFS machines are highly precise, using only the necessary amount of film and minimizing product spillage. By consulting with experienced vertical form fill seal machine manufacturers, businesses can choose machines that are energy-efficient and require minimal maintenance. This reduces operational costs over time, allowing companies to invest resources in other critical areas of their business.

Flexibility for Different Products

Businesses often handle a variety of products with different shapes, sizes, and packaging requirements. Modern vertical form fill seal machines offer flexibility to adapt to these variations. Manufacturers can provide machines that handle multiple types of packaging formats, such as pillow bags, gusseted bags, or sachets. By leveraging the expertise of vertical form fill seal machine manufacturers, companies can ensure that their packaging equipment meets current needs and can adapt to future product changes.

Support and Maintenance

Choosing the right machine is only part of the process. Regular maintenance and technical support are crucial to ensure that VFFS machines continue operating efficiently. Many vertical form fill seal machine manufacturers offer comprehensive support, including installation, training, and troubleshooting. This support helps businesses minimize downtime and avoid costly repairs, keeping the packaging line running smoothly.

Conclusion

In today’s competitive market, efficient packaging is more important than ever. Vertical form fill seal machines offer businesses speed, accuracy, and flexibility in their packaging operations. By working with experienced vertical form fill seal machine manufacturers, companies can access the right technology, gain valuable insights, and improve overall packaging efficiency. From reducing waste to enhancing product quality and boosting productivity, partnering with knowledgeable manufacturers can make a significant difference in how businesses manage their packaging processes. Investing in the right VFFS machine ensures that packaging is not just a task, but a streamlined and efficient part of a successful business strategy.